Gate Hinge, Roller, and Track Repair/Replacement West Hollywood, CA

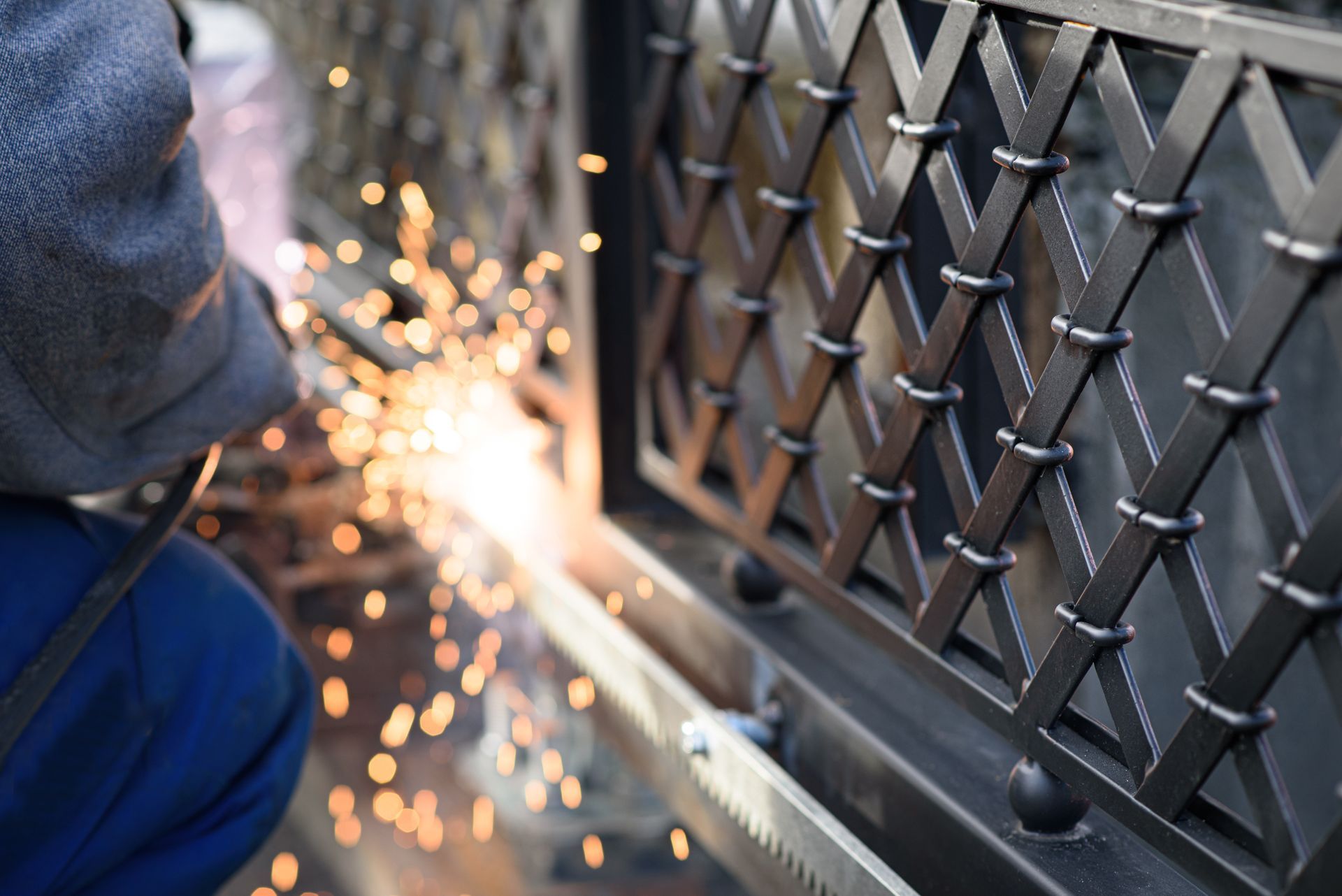

At Hollywood Electric Gates & Custom Metal, we provide expert gate hinge, roller, and track repair/replacement for residential and commercial properties in West Hollywood, CA. With studies from the American Welding Society (AWS) showing that neglected hardware can cut a gate’s lifespan by up to 40%, timely service is essential. Our expertise covers metal gate hinge repair, electric gate hinge replacement, and automatic gate track replacement, ensuring smooth, secure, and reliable operation.

We also handle sliding gate roller repair, driveway gate roller repair, and electric gate track repair, using high-quality materials from trusted brands like DoorKing (DKS) and LiftMaster. Whether you need minor adjustments or complete gate hardware replacement, our team delivers durable solutions that extend the life of your system and keep your gates functioning at their best.

Our Gate Hinge, Roller, and Track Repair and Replacement Services

Gate hardware components are essential for reliable operation and security, with hinges, rollers, and tracks bearing the constant stress of daily use in West Hollywood's varied climate conditions. We specialize in diagnosing and repairing hardware failures that cause gates to drag, bind, or operate improperly.

Common Hinge Problems and Solutions

Gate hinges frequently develop issues from rust, corrosion, and physical damage caused by California's weather exposure and constant operational stress. These problems manifest as gate sagging, uneven swing patterns, squeaking noises, and difficulty opening or closing completely. Loose or broken hinge pins disrupt proper alignment, compromising both security and smooth operation while potentially causing additional strain on gate operators and locking mechanisms.

Heavy gates operating without adequate lubrication accelerate hinge wear through metal-on-metal grinding, creating increased stress that can damage surrounding components and gate frames. Early identification of hinge problems prevents costly secondary damage to gates, operators, and mounting structures. We provide thorough hinge assessments that identify wear patterns, corrosion damage, and alignment issues before they cause complete failure or safety hazards.

Professional Roller and Track Repair Services

Sliding gate rollers and tracks require specialized repair techniques to address common problems like debris accumulation, bearing failure, and track misalignment that cause gates to bind or jump off tracks. We service all roller types including steel ball bearing systems, nylon wheels, and specialty heavy-duty configurations, replacing worn components with upgraded materials designed for California's climate and your gate's specific weight requirements.

Track repair services include straightening bent rails, clearing debris buildup, and realigning tracks for optimal roller contact and smooth gate travel. Our technicians assess track condition, roller wear patterns, and gate alignment to identify root causes of operational problems rather than just addressing symptoms. Complete track replacement is available when repair isn't cost-effective, using heavy-duty materials and precision installation techniques.

Roller and Track Repairs for Electric Gates

We address the common issues affecting rollers and tracks to ensure smooth gate operation. Our approach includes diagnosing roller wear, correcting track misalignment, and upgrading components when necessary to improve performance and longevity.

Roller Malfunctions and Solutions

Rollers are critical to gate movement, and malfunctions often arise from wear, debris buildup, or lack of lubrication. We inspect rollers for cracks, flattened surfaces, or corrosion, which can cause uneven movement or noises during gate operation.

Our repairs typically involve cleaning and lubricating rollers or replacing damaged ones with high-quality, weather-resistant models. Proper roller function reduces strain on the gate motor and prevents further mechanical issues, ensuring safer and quieter operation.

Track Alignment and Adjustment

Misaligned or bent tracks prevent gates from sliding smoothly and can lead to jamming or increased wear on rollers. We carefully assess track straightness and attachment points, looking for bends, warping, or debris accumulation.

Using precision tools, we realign tracks and secure loose fittings. We also clear any obstructions like dirt, leaves, or rust that impair movement. Correct track alignment decreases operational resistance and extends the lifespan of gate components.

Upgrading Rollers and Tracks

Upgrading rollers and tracks improves gate reliability and reduces maintenance needs. We recommend replacing outdated steel or plastic rollers with sealed ball-bearing rollers to enhance durability and reduce friction.

For tracks, we suggest heavy-duty galvanized steel tracks to resist corrosion and warping, especially in coastal areas like West Hollywood. Installing newer components can enhance gate speed and reduce noise, providing a more efficient and long-lasting electric gate system.

Why Choose Hollywood Electric Gates & Custom Metal

We focus on precision, durability, and customer satisfaction in every project we undertake. Our approach combines skilled professionals, premium materials, and a commitment to meeting your expectations.

Expert Technicians

Our technicians have extensive experience specifically with gate hinges, rollers, and tracks. We handle complex issues, including misalignment, wear, and mechanical failures, with accuracy. Each technician undergoes ongoing training to stay current with the latest repair techniques and industry standards. We inspect every component thoroughly before recommending repair or replacement. This ensures that solutions are long-lasting and minimize future downtime. Our team also prioritizes safety and follows local building codes in all repairs.

High-Quality Materials

We use only materials that meet or exceed standards for gate hardware. This includes corrosion-resistant metals and industrial-grade rollers designed for smooth operation and durability. Choosing these materials helps extend the lifespan of your gate system. Our supply chain includes trusted manufacturers to guarantee consistency and availability. We also customize solutions when needed, matching parts to your gate’s specific design and load requirements.

Satisfaction Guarantee

We stand behind our work with a clear satisfaction guarantee. If any repaired or replaced part does not perform as expected, we handle adjustments or replacements promptly. Our goal is to provide reliable service that fits your schedule without surprise costs. Communication is key; we keep you informed at every step of the process. Our warranty coverage and transparent pricing further ensure confidence in our services.

Gate Hinge, Roller, and Track Repair/Replacement FAQ's

How much does gate hinge replacement cost?

Gate hinge replacement typically costs $150 to $800 depending on hinge type, gate size, and installation complexity. Basic residential hinges start around $150 per pair, while heavy-duty commercial hinges for large gates cost $400-800. The price includes removal of old hinges, new hinge installation, and adjustment for proper operation. Specialty hinges for automated gates or custom applications may cost more due to specific load requirements.

What's the best roller system for heavy sliding gates?

Steel ball bearing roller systems are best for heavy sliding gates due to superior weight capacity and durability. V-groove steel rollers with sealed bearings handle weights up to 2,000 pounds while providing smooth, quiet operation. For extreme applications, tandem roller configurations distribute weight across multiple contact points. Steel rollers outlast nylon alternatives and require less frequent replacement on heavy commercial gates.

Can you repair bent gate tracks without full replacement?

Yes, many bent gate tracks can be straightened and repaired without full replacement depending on damage severity. Minor bends and dents can often be hammered out and re-aligned for proper roller operation. However, severely damaged tracks with multiple bends or structural compromise require replacement for safe operation. We assess each situation to determine the most cost-effective repair approach.

How long does gate track repair take in West Hollywood?

Gate track repair typically takes 2-4 hours for straightforward repairs like roller replacement or minor track adjustments. More complex repairs involving track straightening or partial replacement can take 4-8 hours. Complete track replacement projects may require a full day depending on gate size and access conditions. We provide time estimates after assessing the specific repair needs.

What causes gate rollers to stop working properly?

Gate rollers fail due to debris buildup in tracks, worn bearings from age and use, lack of lubrication, and damage from gate misalignment. Weather exposure causes rust and corrosion in non-sealed rollers, while overloading exceeds weight capacity. Poor track maintenance allows dirt and leaves to jam roller movement. Regular cleaning and lubrication prevent most roller problems and extend their lifespan significantly.